Aluminum & Glass Hybrids in PEBs: The New Standard for Modern Retail Builds

Steel PEBs: The Smart Foundation for Modern Sports Facilities

Why Steel is Winning in Recreation

Steel sports facilities are gaining popularity due to unmatched durability, design flexibility, and cost efficiency. Clear-span PEB structures create open, versatile interiors ideal for sports halls, gyms, and courts. With global commercial construction expanding at 8.5% CAGR , steel plays a key role in high-demand public and private sports infrastructure.(tallsteelbuilding.com+7universalsteel.com+7hintonbuildings.com+7.)

Core Advantages of Steel PEB Gyms

1. Clear-Span Flexibility

Steel trusses allow large, column-free interiors—essential for basketball courts, indoor tennis, or multi-use gymnasiums.

Higher Ceilings & Better Acoustics

Supports tall rooflines, acoustic panels, and unobstructed play areas.

2. Durability & Low Maintenance

Steel resists warping, pests, mold, fire, and seismic stresses—ideal for high-traffic and outdoor-exposed sports environments.

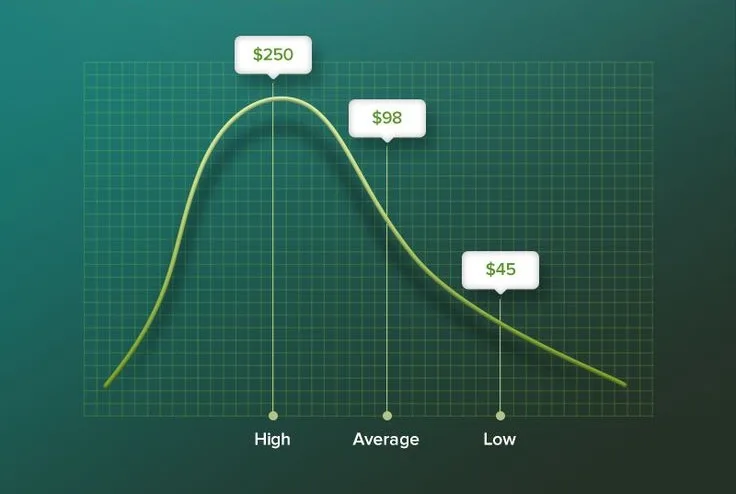

3. Cost-Effective Delivery

Factory fabrication reduces onsite labor and foundation costs—delivering savings for municipalities, schools, and other organizations.

4. Rapid Installation

PEB sports halls can be assembled in weeks, enabling faster community opening and user access.

5. Sustainability & Longevity

Steel structures are infinitely recyclable and energy-efficient when coupled with insulated panels. Their life span translates to better long-term ROI.

CityTech Group’s Contribution

We design sports-ready PEBs for gyms, courts, and halls—with acoustic systems, mezzanines, skylights, and turnkey finishes—helping communities launch active spaces without construction delays.

Conclusion

Whether it’s a kids’ soccer league, college gym, or public rec center, steel PEBs deliver open space, strength, and cost savings. They support rapid launch, low upkeep, and flexible layouts. So, if your next sports facility could be ready faster, stronger, and more affordably, would you choose steel PEBs?

Are you ready to build with the future in mind? Reach out to CityTech Group or connect directly with Adnan Rafique to bring these steel innovations to your next project.