Services

Pre Engineered Steel Building

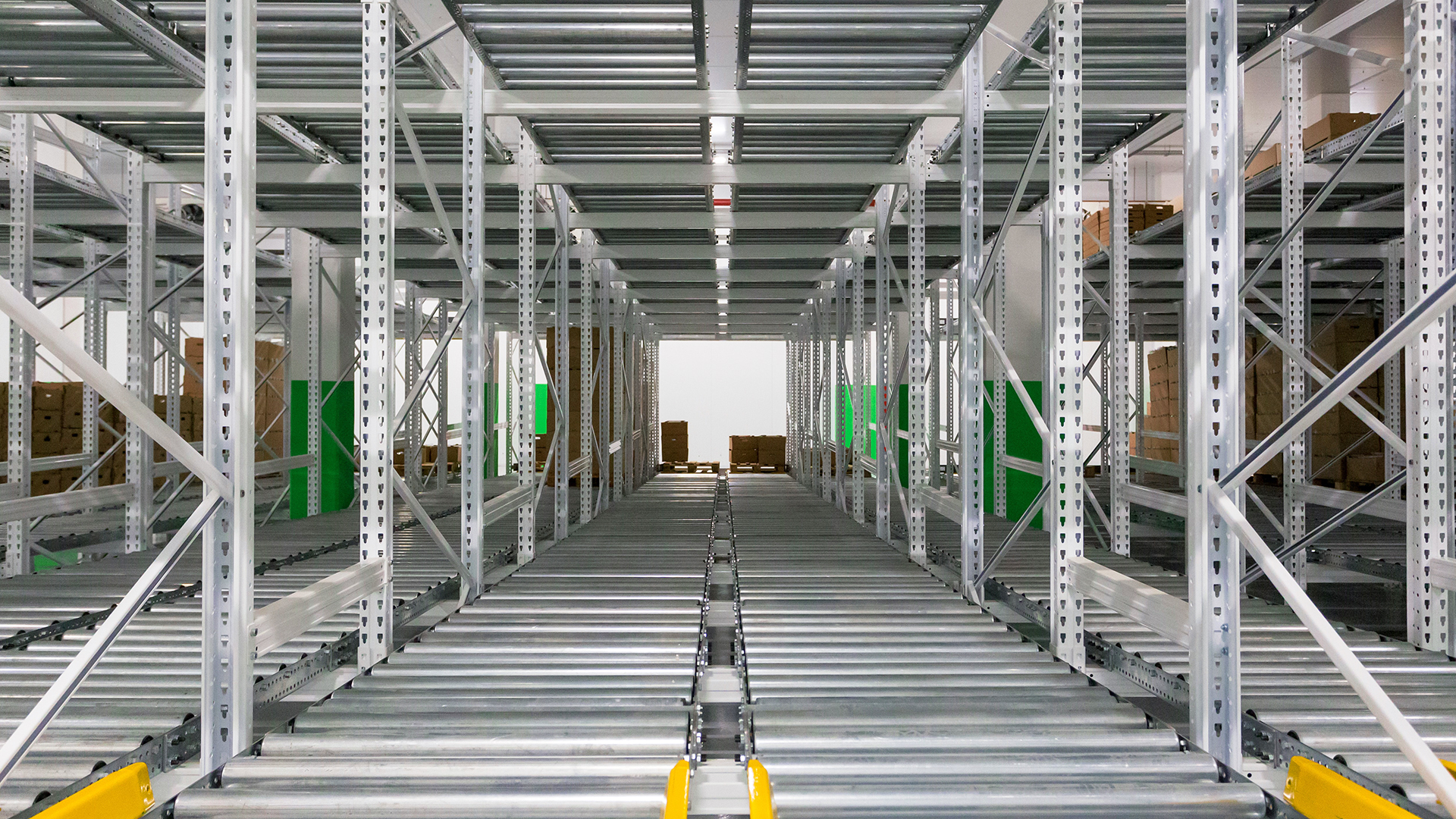

PEB steel buildings construction services (PEBs) are favored construction material across various commercial, institutional, residential, and industrial industries. PEBs are constructed using pre-designed and pre-fabricated parts produced off-site and assembled on-site. This means faster construction, efficiency, and design flexibility. This solution helps to lower the cost of pre-engineered steel buildings. PEBs are popular in factories, showrooms, hangars, warehouses, and other locations.

PEB manufacturers specialize in steel building construction, providing specialized designs and effective project management. Reducing material waste ensures quality control, safety compliance, and cost savings. Skilled engineers and architects are crucial to designing practical and aesthetically pleasing PEB building designs and structures.

In the United Arab Emirates and Dubai, reliable PEB businesses offer comprehensive PEB solutions that result in high-quality construction and satisfied clients. Pre-engineered metal commercial buildings offer ample space, architectural flexibility, and durability, making them ideal for retail and office spaces. PEBs are also perfect for temporary or movable structures as they can be easily disassembled and moved.

CityTechEng : Your Trusted Partner for Buildings Construction Services

Are you looking to bring your architectural dreams to life? Look no further than CityTechEng - your premier partner for top-notch buildings construction services. With a track record of excellence and a passion for delivering exceptional results, we are committed to turning your vision into reality.

Steel Standard

The CityTech’s PEB building steel structure comprises several components:-

- primary rigid frames

- end wall bearing frames

- secondary structural members (Purlins & Girts)

- wall and roof sheeting

- bracing components

This construction project involves structural components such as mezzanines, roof monitors, roof extensions, canopies, fascias, parapets, partitions, and roof and wall-framed openings. Additionally, anchor bolts, connections, and fasteners are utilized to secure all the elements in place.

Building’s Length And Width

The building length refers to the distance between the outside wall girts in opposite end walls for by-pass end walls or between the outside flanges of end wall columns in opposite end walls for flush end walls. It is a combination of several bay lengths.

The building width refers to the measurement from the outside of one girt/block wall to the outside of the girt/block wall on the opposite outside wall.

End Bay and Interior Bay Length

The end bay length refers to the measurement from the outer edge of the girt or block wall to the center point of the initial interior frame columns.

The interior bay length is the distance between the center lines of the columns of two adjacent mainframes. In warehouses, the most commonly used bay lengths are 6m, 7m, 8m, 10m, and even up to 12m.

Building Height and Roof Slope

The building height is determined by measuring the distance from the base plate of the main frame column to the outer point of the eave purlin at the top. In cases where the columns are either recessed or elevated from the finished floor, the eave height is measured from the finished floor level to the top of the eave purlin.

The roof slope refers to the angle of the roof with the horizontal. The roof slope in the metal building industry is usually expressed as either 0.5 or 1.0 in 10. The two most commonly used roof slopes are 0.5 in 10 and 1 in 10, but any feasible roof slope can be used.

When requesting a quotation, it is important to specify if a design is needed for snow, earthquake, collateral, crane, or any other loading condition. Unless otherwise requested, all loads will follow the latest American codes and standards applicable to PEB building design.

Rigid Frames

CityTech’s Primary Rigid Frames

Below are the most commonly used primary framing systems, which are symmetrical around the ridge line and feature multi-span/multi-gable framing. While it is possible to have framed with unequal modules, this option may require more engineering time and a longer delivery period.

- CityTech’s Jack Beams

- Mezzanine System

- Crane System

1. CityTech’s Jack Beams

At CityTech, Jack beams offer an affordable and secure way to extend bay lengths when a large, unobstructed space is needed. Using Jack Beams, common bay lengths of 5, 6, 7, 8, 9, 10, and 12 meters can be doubled, resulting in clear bay lengths of 12, 15, 16, 18, and 20 meters.

If a customer requests a 16-meter bay length instead of the more cost-effective 8-meter option, Jack Beams can be used on the inside and outside walls of the building to accommodate this. Overall, Jack Beams are a versatile solution for creating open spaces in any construction project.

2. System

CityTech can support crane systems by providing column/rafter brackets, crane runway beams, and lateral ties. We request that customers provide complete crane information from the manufacturer to design and estimate crane buildings.

Pre-engineered steel buildings' most common crane systems are top-running, under-hung, jib, monorail, and gantry cranes.

3. Mezzanine System

A mezzanine system creates an additional floor in a building, with independent support columns, main beams, joists and deck panels making up the structure.

Depending on the design, the columns may be square tubes or built-up sections, and the beams or joists can be connected directly to the main frame columns.

Mezzanine beams are typically built-up I section that span in the direction of rigidity, while mezzanine joists are built-up or hot rolled I section, spaced at 1.5 m for a 10 mm thick concrete slab. Joists connect to mezzanine beams with a flush-type connection.

The clear height beneath the mezzanine is generally 3m above the finished floor level. The mezzanine's concrete slab must be designed to withstand dead, live, and collateral loads. The mezzanine deck fasteners are 5.5 mm diameter self-drilling screws with hexagonal thread nuts spaced at 333 mm without scaling.

Get in Touch today!

Do not hesitate to contact us if you require guidance or support with the building process. We are here to support you at every stage.